Supply chain operations are not only indispensable to the retail ecosystem but also complex. From carriers to shippers to retailers, everyone is attempting to place the right good at the right time with minimal disruption. It’s indeed daunting.

Disparate systems that every partner works in the supply chain make things worse. It’s because disparate systems make data alignment a challenge.

Moving towards agility and adopting newer technologies is undoubtedly a step in the right direction, but data integrity and data collaboration are the needs of the hour to move towards robust supply chain management, especially at a time when an economic slowdown looms large.

In this piece, we shall understand how data and analytics have a major role to play in the different layers of SCM, especially when times aren’t quite favorable.

Data: The New Viable Currency of the SCM

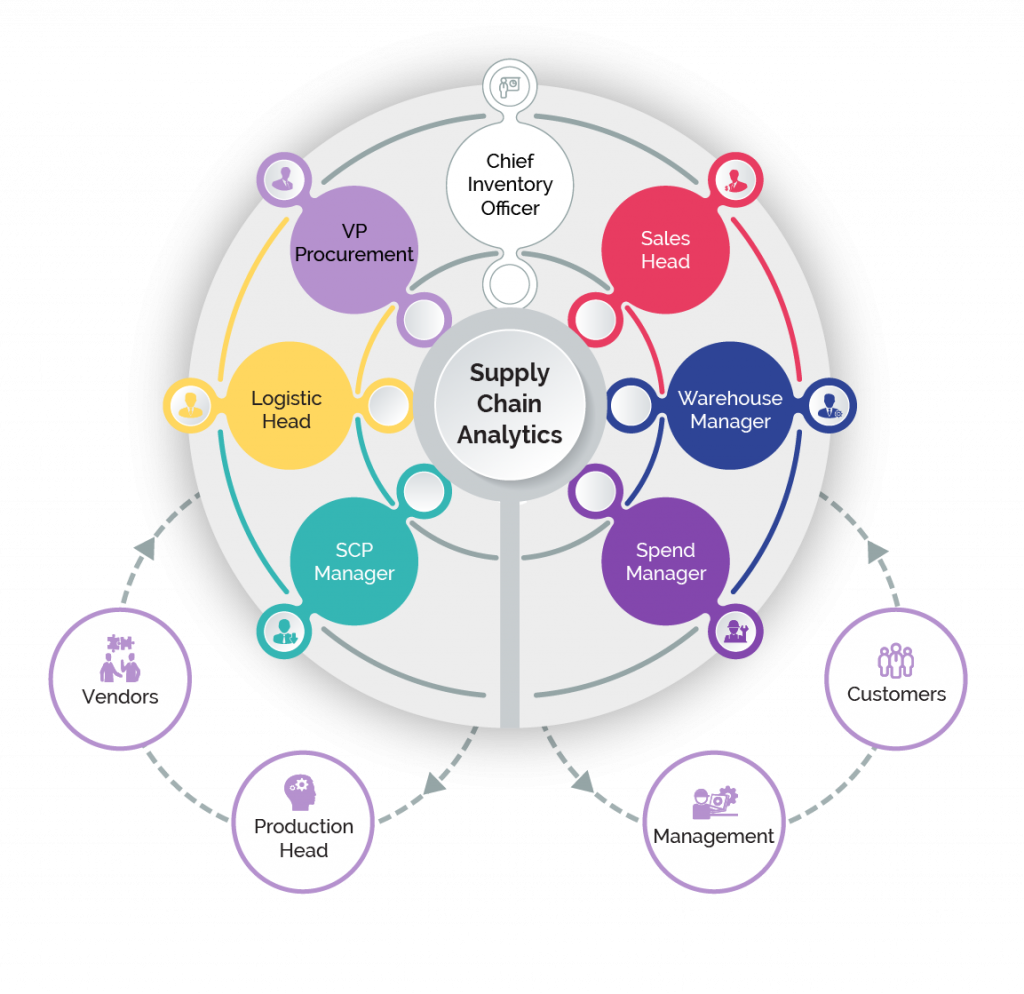

Before we delve into the touchpoints where data can have a major impact, let’s quickly understand the SCM landscape.

Better data visibility delivers descriptive, diagnostic, predictive, and prescriptive actionable insights, but how does it enable each partner involved in the system?

Besides the one mentioned above, there are some indirect benefits of data breakthroughs in SCM.

Vendors

- Visibility on invoice & payments

Production Head can monitor

- Productivity and capacity utilization

- Product cost

- Machine utilization

- Preventive maintenance

For the Management, data offers

- Unified performance parameters

- Consolidation across organization

- Ease of customization & scalability

- Platform agnosticism

Last but not least, the improvements at every layer lead to customer delight, as customers can experience perfect order fulfilment and seamless return processes.

How does data add to the efficiency of SCM?

Data systems not only offer insight into the internal data but also have a connected data system right from your manufacturers to the final delivery of products so that they are easily accessible as and when needed.

Some of the primary benefits of having the right data at the right time in the SCM are:

- Ability to adjust quickly to an unanticipated change

- Timely delivery of products and materials

- Maintain the quality of the final products

- Quickly opt for corrective measures

- Combat outside forces that threaten the supply chain

- Move from siloed systems to new-age technology

How to enhance supply chain visibility?

Supply chain managers must ensure they have the right product at the right place and at the right time, budgeted properly, and replenished as per their needs. However, for that, they need access to real-time data.

What tools can help?

- Customizable databases

- Easy access to supplier data

- A single source of truth

- Short implementation time to serve customer needs

Final Thoughts

It is urgent for retailers to have visibility throughout the entire supply chain. Clarity is crucial, especially in times of disruption and uncertainty, so that organizations can have operational efficiency while delivering excellent customer service. However, the only way to achieve this kind of visibility and control is to invest in the right kind of data and analytics eco-system that digs into the supply chain operations like a pro.

- Revolutionize Your Retail Operations: How Oracle SIOCS Transforms Inventory Management - April 17, 2024

- Strategic Insights: Exploring the Benefits of Oracle’s Merchandise Financial Planning - March 26, 2024

- Mastering Change: A Closer Look at Oracle Xstore POS Version 23 with Aspire’s Expert Touch - March 4, 2024

Comments